laboratory test

Test setup

Customer specific tes setups are the base to simulate durability and Performance:

- In cooperation with the customer we develop a test setup which fits best to the demands of the product. We offer a variety of pre set up tests.

- Target of our testings is to establish a serious test to compare the product with comparable tools on the market.

torque testing

The torque testing delivers data for the comparison of material characteristics, hardening processes and geometry. The following issues can be tested:

- Maximum torque and torsion angle

- Yield point: torque until the irreversible deformation of the material

- Durability: constant testing

- Metallographic micrograph

- Hardness depth

- Spectral analysis

Hardness in HRV and HV

Optical measuring

Tolerances compare to drawing

Special measuring of geometry

live applications:

Our live applications are tailor-made solutions for our customer, because they know best how and where their product is used. We simulate the main application 1:1. Our focus is to tune the testing conditions in whole, which means that we secure that fastening tool and fastener fits perfect together. Only by this test setup we can ensure that the testing results of performance, durability and safety are realistic and can be compared with competitive products.

operator quality

Here are criterias in the focus which can not be quantifiable named but which are decisive for the end user to make a buying decision. They are called “Soft-Facts” and reflect the subjective impressions of the consumer.

Some examples:

- Optic -> attractive design

- Handling -> results from the application test

- Haptic -> surface

- Quality of marking

- Optical wear

- Optical signs of wear

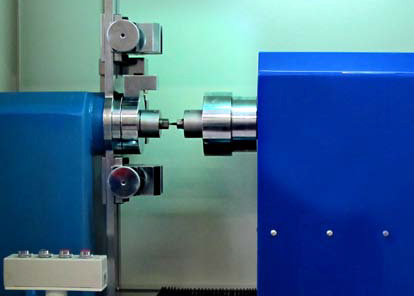

breaking test layout

nutsetter in hardness test

testing equipment for durability and maximum endurance testing